Why Us

Explore our cutting-edge range of Non-Destructive Testing(NDT)

products designed to

deliver accurate,reliable,and durable results

across various industries.

Body Armour

GNAT Technologies played a critical role in ensuring the safety and protection of military personnel by conducting extensive NDT inspections on 20,000 body armour components using advanced digital radiography techniques. Our state-of-the-art equipment allowed for precise detection of fine line cracks that could compromise the integrity of the body armour. By identifying and addressing these issues, we helped to safeguard the lives of countless soldiers in the field.

Rubber Seal

GNAT Technologies utilised advanced digital radiography techniques to meticulously inspect the rubber seals on metal specimens following production. Our high-resolution imaging capabilities allowed for precise detection of any defects or inconsistencies within the rubber seals, ensuring their integrity and functionality in critical applications.

Insurance Investigation

Insurance companies have a duty to undertake root cause analysis, and this can be particularly hard when all that's left is a melted mess. Using our high-tech X-ray facility, we can provide insights that otherwise would be impossible. Through the melted mess we were able to get granular and assess the condition of a wire in the fuse of a plug, giving the client added confidence in their analysis.

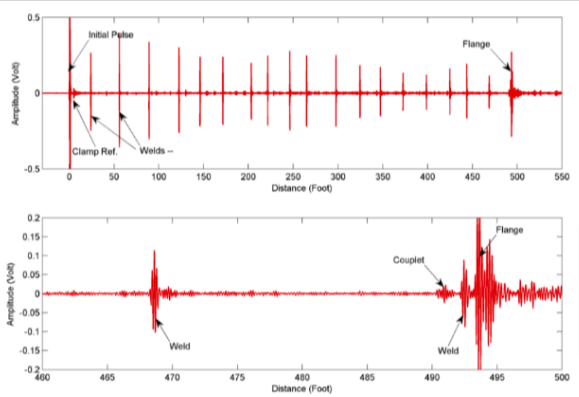

EMAT - Long range UT Guided Waves

This innovative NDT technique allowed us to efficiently evaluate the structural integrity of these critical components over long distances, minimising disruption to traffic flow. By utilising guided waves, we were able to detect potential defects or damage that could compromise the safety of the highway infrastructure, ensuring the ongoing reliability and durability of the suspenders.

This advanced NDT technique enabled us to efficiently evaluate the pipeline's structural integrity over extended distances, minimising disruptions to gas supply. By utilising guided waves, we were able to detect potential defects, corrosion, or other anomalies that could compromise the safety and reliability of the gas transmission line, safeguarding both the infrastructure and the surrounding environment.

.png)

Hydropower Inspection

Successfully employed eddy current and magneto-resistive sensor technology to conduct comprehensive inspections on hydropower structures, effectively detecting cracks in welded structures beneath paint layers.

This innovative NDT technique provided sensitivity comparable to magnetic particle inspection (MPI) while overcoming the limitations of traditional methods. By utilising eddy current and magneto-resistive sensors, we were able to accurately identify and assess defects, ensuring the structural integrity and safety of hydropower facilities.

Tarmac Reinstatement Testing

To test the quality and durability of repaired or replaced tarmac surfaces, typically roads or parking lots. It involves a series of tests to assess the physical properties and performance of the reinstated material. One transmitting antenna radiates a short pulse of electromagnetic energy into the subsurface, whilst multiple receiving antennas record the reflection at different antenna offsets.

By conducting these tests, we could verify that the reinstated tarmac meets the required standards and specifications, ensuring its long-term performance and safety.

Ultrasound - assisted recovery of valuable metals from waste lithium-ion batteries

The use of high intensity ultrasound to enhance the delamination of the electrode assembly bonding thus enabling more effective material recovery particularly of valuable metals. Alongside using giant-magneto-strictive ultrasonics to support high intensity and multi mode/direction cavitation operation. This will yield more efficient metal recovery.

Penetrant

- 9 Meter long FPI System suitable for testing 1000 mm long parts.

- Has both post-emulsifiable and water-washable penetrants process.

Magnetics

- Three-phase full-wave DC / AC MPI machine.

- Digital metering and variac control to achieve linearity even at low current values.

- Current output – 4000 amp for circular & 15 kA at 350 mm dia coil for longitudinal magnetization.

- Demagnetizer - 350 mm port.

Radiography

- In-house x-ray facility (2 x-ray bays with up to 320kv capability).

- Two separate radiography bays for handling large and small components.

- Powerful x-ray generating machines suitable for thin-walled as well as thick-walled parts.

Eddy Current

- Complete facilities with portable impedance unit to Phase Analysis Laboratory Equipment.

- Frequency range from 100 Hz to 10 MHz with a complete array of test blocks and probes.

Ultrasonics

- Initially, the facility will have portable units with the intention of providing full capability with immersion testing.

- Full set of calibration blocks.

- All types of straight and angular probes.

Calibration & Lab testing

- Calibration and analysis of NDT equipment and consumables.